PRODUCTS

WearGuard®

WEARGUARD

An Industry Game

Changer

WearGuard® is a ceramic-based bearing system which is the leading solution for extending campaign times in continuous steel sheet galvanizing operations. This technological innovation allows manufacturers to operate at higher efficiencies and consequently has become the industry benchmark.

Our commitment to our customers and continuous quality improvement forms the cornerstone of our philosophy. Our skilled engineers work exclusively with you to custom-design WearGuard Bearings for retrofitting your pot rolls, so you can experience a smooth and quick transition. Call us and begin realizing the benefits of less downtime, reduced strip vibration, and increased prime product.

McDANEL INNOVATION

How the WearGuard®

system is different

001

In every industry, there comes a time when a technological innovation changes the way everything operates.

For the galvanized steel strip industry, that innovation is WearGuard® Ceramic Bearings, the leading solution for extending your pot roll life.

Change the Way You

Operate

002

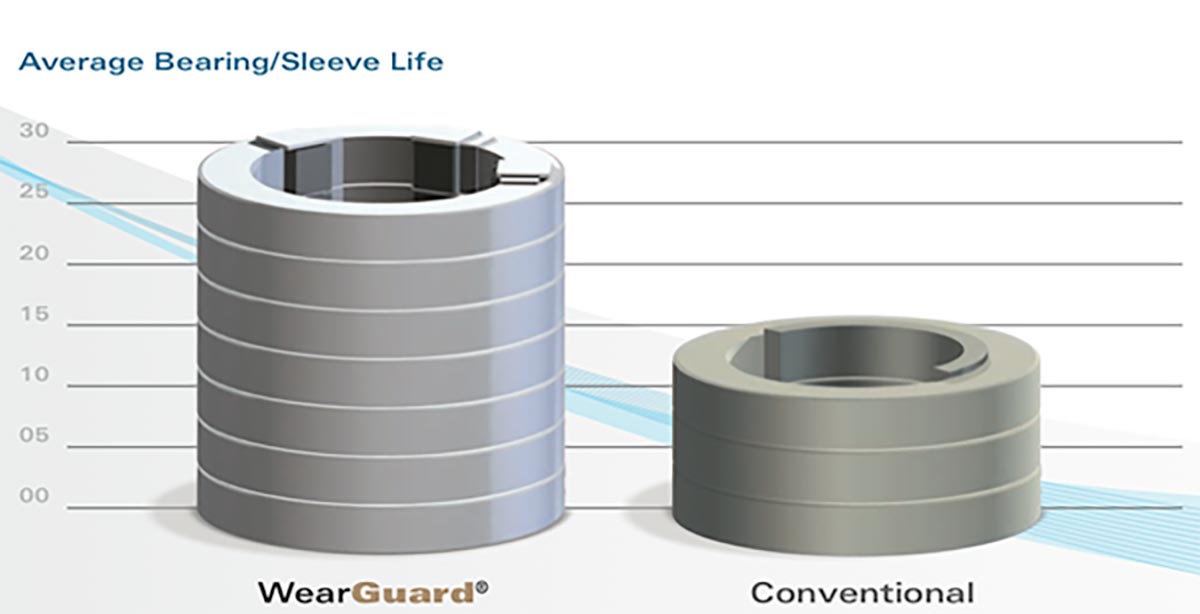

WearGuard Bearings have longer life over conventional bearings. This means less line shutdowns to change bearings, increasing your production time and your cost savings.

Dramatically Reduced Downtime

003

When you introduce WearGuard Bearings to your pot rolls, you’re adding to your bottom line by keeping your line running longer with less wear and greater stability.

Keep on Rolling

004

The geometrical stability and high wear resistance of WearGuard Bearings allow smooth operation of the stabilizer rolls, which minimizes strip vibration and consequently, coating thickness variation.

Reduce Strip Vibration

005

The WearGuard Bearing system is inherently low friction because of the choice of materials and the arrangement of the components. The result is smooth start-ups and easy restarts after line stoppages over a wide range of strip gauges and without strip marking.

Start, Stop and Restart Smoothly

006

Enhanced wear resistance, low friction and the dimensional stability of WearGuard, enables you to produce top grade product maximizing your bearing campaign yield. This is particularly advantageous for producers of exterior grade automotive products.

Produce More Prime Product

007

Each WearGuard Assembly consists of a stainless steel housing containing three advanced ceramic bearing bars. This system was designed exclusively for use with galvanizing sink and stabilizer rolls.Enhanced wear resistance, low friction and the dimensional stability of WearGuard, enables you to produce top grade product maximizing your bearing campaign yield. This is particularly advantageous for producers of exterior grade automotive products.

Advanced and Proven Ceramic Technology

008

- Provides excellent wear resistance

- Low coefficient of friction enables the rolls to turn more easily on start-up or restarting the line after a stoppage

- Excellent thermal shock resistance, meaning WearGuard Bearings do not require pre-heating or special caution during removal from the pot between campaigns

- Capable of withstanding high compressive loads, which means it can be used in a wide range of line operating conditions

- Offers extreme corrosion resistance to molten zinc

- Tolerates the impact of dross build-up better than other materials because of its high hardness

Why WearGuard Advanced Ceramics?

009

For more than 90 years, McDanel Advanced Ceramic Technologies has developed specialized expertise in the advancement of ceramic-based solutions for major industries worldwide. We are a ceramic design and engineering company, which utilizes ceramics to meet our customers’ needs.

Produced by a Leader in

Advanced Ceramic Technologies

010

Our commitment to our customers and continuous quality improvement forms the cornerstone of our philosophy. Our skilled engineers work exclusively with you to custom-design WearGuard Bearings for retrofitting your pot rolls, so you can experience a smooth and quick transition.

Call to begin realizing the benefits of less downtime, reduced strip vibration, and increased prime product.

Designed to Fit Your Operation

McDANEL SERVICES

We are here

to collaborate with your team

McDanel is different than other industry suppliers in that their customer service is responsive and creates positive solutions. We can count on McDanel to perform professionally and support our needs.

McDanel Customer

We value working with McDanel because we both hold high values of collaboration and moral duty to facilitate a win-win relationship. McDanel understands their products are critical components to ours. Authentic interest in our company's well-being is conveyed which is largely not found in today's supply chain.

McDanel Customer

McDanel has helped our company solve the challenge of partnering with a ceramics industry supplier that can provide reliable and repeatable products. McDanel has worked in collaboration with our team over the years to hold tight tolerances and back their products if issues arise.

McDanel Customer

The quality at McDanel is better than other companies and customer satisfaction is very high. Additionally, we can rely on McDanel to respond promptly to our detailed needs. Also, productivity has increased due to improved yield in assembly by using McDanel ceramic tubes.

McDanel Customer

We order our ceramic components only from McDanel. Even if we could save money with another supplier, we wouldn't switch. We are not cost sensitive, we are quality sensitive.

Allen T. McDanel Customer

I love the variety of what we do. We start with something raw and make it remarkable. I love this because the ideation goes from beginning to end.

Tony Finoli, PhD Manager of Application Engineering

What got me interested in ceramics is the fact that ceramics enable technologies that can’t be done in any other way.

John Dodsworth, PhD Chief Technology Advisor